- Proof of concept (POC) prototype to finished product development

- Mechanical testing: FEA analysis, tensile testing, radial and compression testing, product life cycle testing

- Electrical testing: 60601 compliance

- Software verification and validation (Limited)

- Quality and regulatory support

- Usability and clinical testing

- Development documentation (DHF in accordance with QSR and ISO requirements)

Top Capabilities

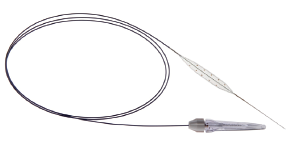

Coil Winding

Standard and custom coil winding for micro coils, catheter reinforcement, etc.

Coil winding capabilities:

- Wire size: 0.0004” to 0.0025″ (and higher as necessary)

- Mandrel size (Coil ID): 0.0015” to 0.136″

- Materials: Stainless Steel (SS), platinum alloys, Nitinol, coated copper, and more

- Pitch: Closed, open, and variable pitch

- Coil lengths from 0″ to 80″

- Left or right-hand winding

- Single or multifilar

3D Printing

3D printing for fixtures/models, one-off prototypes, and pilot production runs.

Accessable Technologies:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA) or Digital Light Projection (DLP)

- Selective Laser Sintering (SLS)

- HP – Multi Jet Fusion (MJF)

- Carbon 3D – Digital Light Synthesis (DLS, enabled by CLIP)

- Direct Metal Laser Sintering (DMLS)

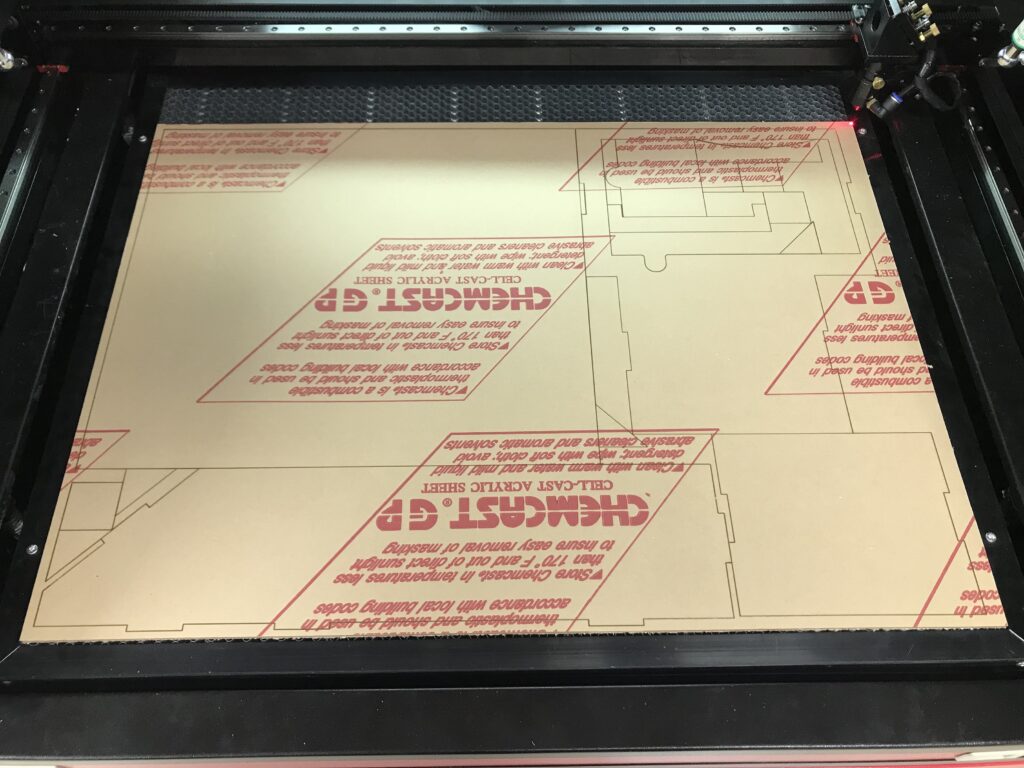

Laser Cutting

Laser cutting and engraving for fixtures, one-off prototypes, and pilot production runs.

Outline:

- Flat and cylindrical (rotary) cutting capabilities

- Materials for Cutting: Plexiglas/Acrylic, wood, bamboo, rubber, leather, cork, etc.

- Materials for Engraving: those above plus; ceramics, crystal, glass, marble, painted/anodized metals, etc.

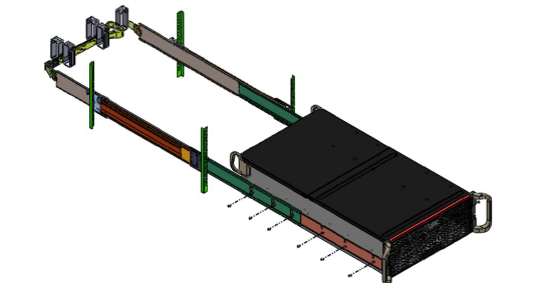

CNC Machining

Small and large scale machining solutions.

Types on CNC machines available:

- Mills

- Lathes

- Plasma Cutters

- Press Breaks

- Robot Welders

- Electric Discharge Machines (EDM)